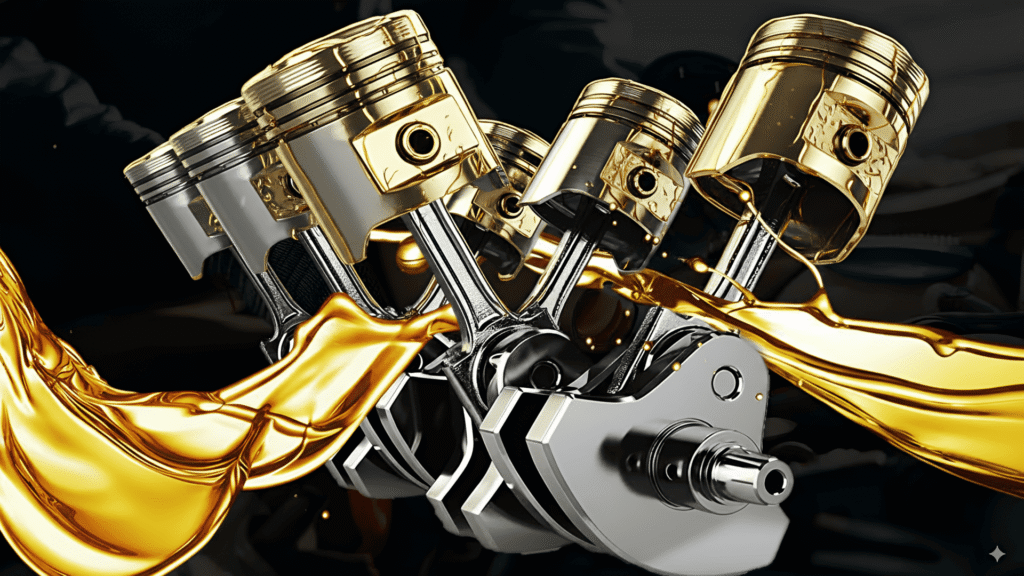

Combustion-driven environments expose lubricants to high temperatures, fuel/soot contamination, and catalytic surfaces. Without robust additive systems, oxidation, sludge/varnish formation, wear, and acid build-up quickly compromise engine durability and fuel economy.

Antioxidants (amine/phenolic), AW/EP (e.g., ZDDP within phosphorus limits), detergents (overbased sulfonates/phenates), dispersants (succinimide/ester), friction modifiers (organic molybdenum/OFMs), anti-foam, corrosion/metal deactivators (triazoles), pour point depressants and VI improvers as needed.

Noack volatility (ASTM D5800), HTHS viscosity (ASTM D4683), CCS/MRV (ASTM D5293/D4684), TEOST (ASTM D6335), copper corrosion (ASTM D130), foam (ASTM D892), RPVOT (ASTM D2272) for oxidation screening, TBN/TAN (ASTM D2896/D664).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3823

|

Dispersant/Detergent

|

Dosage not specified

|

|

PX 3841

|

Anti-foamant

|

0.05 – 0.30

|

|

PX 3849

|

Extreme Pressure/Antiwear

|

0.5 – 1.0 Marine

|

|

PX 3847

|

Extreme Pressure/Antiwear

|

0.5 – 1.0 Marine

|

|

PX 3822

|

Dispersant Detergent

|

2.0 – 10.0

|

|

PX 4005

|

Dispersant

|

5.0 – 15.0

|

|

PX 4006

|

Dispersant + Lubricity

|

2.0 – 15.0

|

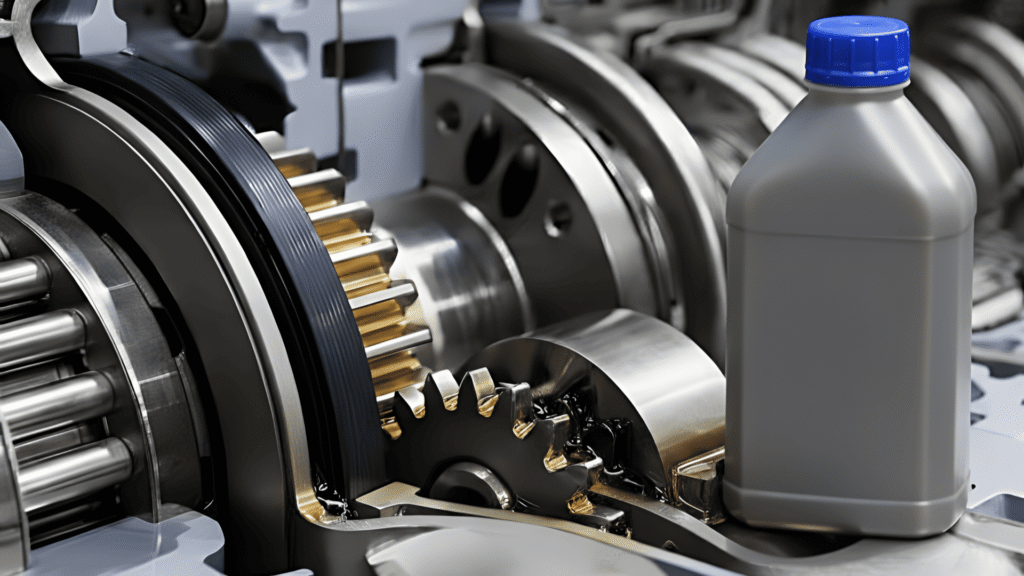

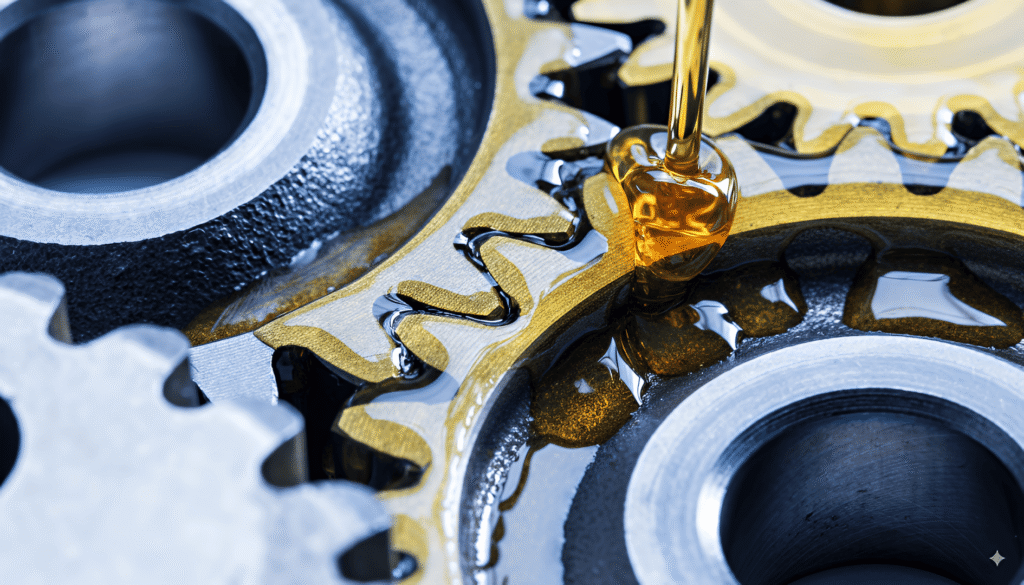

Hypoid and heavy-duty gear sets operate with high sliding and Hertzian contact stresses, demanding EP performance and thermal robustness to prevent scuffing, pitting, and micropitting.

Sulfur–phosphorus EP packages, AW agents, friction modifiers (for synchronized transmissions), antioxidants, anti-foam, corrosion inhibitors/metal deactivators, demulsifiers.

FZG scuffing/micropitting (ISO 14635/ISO 15144), 4-ball EP/wear (ASTM D2783/D4172), copper corrosion (ASTM D130), foam (ASTM D892), demulsibility (ASTM D1401).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3823

|

Dispersant/Detergent

|

0.5 – 2.0

|

|

PX 3825

|

Friction Modifier

|

0.1 – 1.5

|

|

PX 3841

|

Anti-foamant

|

0.05 – 0.30

|

|

PX 3849

|

Extreme Pressure/Antiwear

|

0.5 – 1.5

|

|

PX 3846

|

Extreme Pressure/Antiwear

|

0.5 – 1.5

|

|

PX 3862

|

Corrosion Passivator

|

0.1 – 0.5

|

|

PX 3871

|

Friction modifier Grease Thickener

|

0.3 – 1.5

|

|

PX 3872

|

Friction modifier Grease Thickener

|

0.3 – 1.5

|

|

PX 4005

|

Dispersant

|

1.0 – 2.0

|

|

PX 4006

|

Dispersant + Lubricity

|

1.0 – 2.0

|

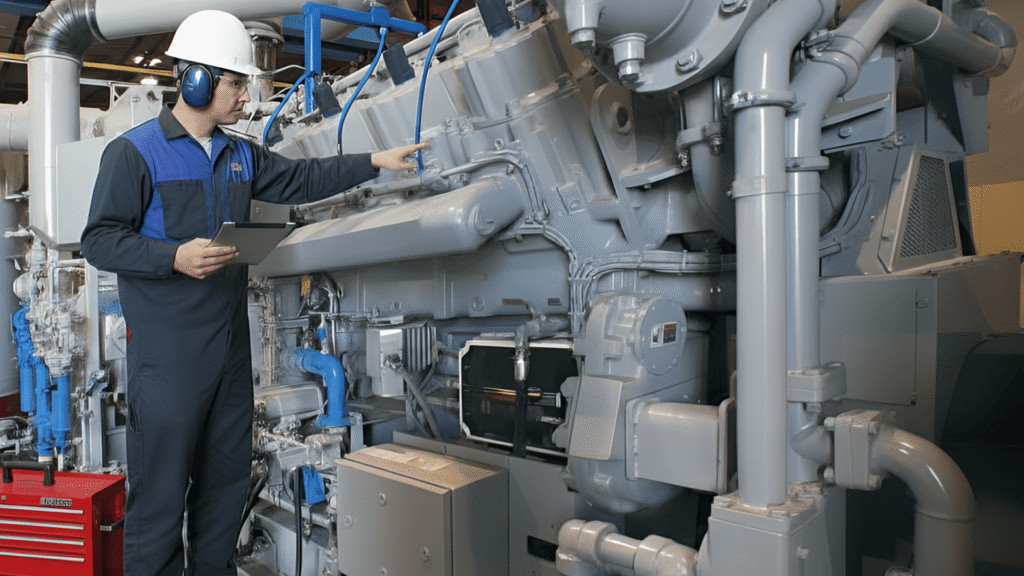

Spark-ignited gas engines experience high oxidation and nitration with lean burn conditions; low-ash requirements protect combustion hardware and aftertreatment.

Antioxidants (high-temperature), low-/medium-ash detergents (overbased), ashless dispersants, AW, anti-foam, metal deactivators; gas-engine-specific detergency packages.

RPVOT (ASTM D2272), TBN/TAN (ASTM D2896/D664), FTIR nitration/oxidation, deposit tests (TEOST), copper corrosion (ASTM D130).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3811

|

Oxidation Inhibitor

|

1.0 – 4.0

|

|

PX 3806

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3807

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3841

|

Anti-foamant

|

0.05 – 0.30

|

|

PX 4005

|

Dispersant

|

2.0 – 10.0

|

|

PX 4006

|

Dispersant + Lubricity

|

2.0 – 10.0

|

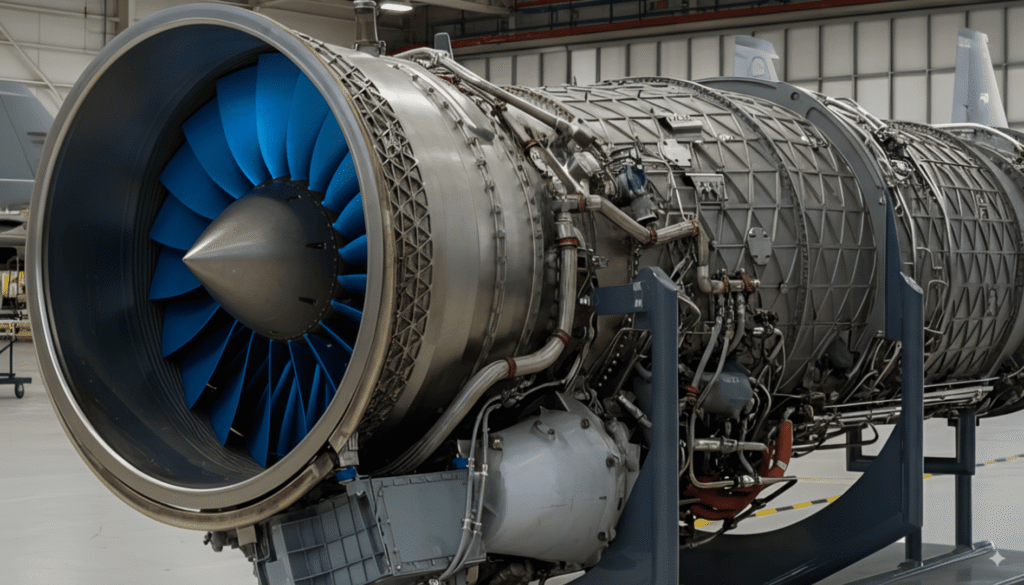

Aviation turbines (often ester-based fluids) require exceptional thermal/oxidative stability and deposit control under high bulk and skin temperatures.

High-performance antioxidants (amine/phenolic), metal deactivators (triazoles), anti-foam, rust/corrosion inhibitors; deposit-control synergists compatible with synthetic esters.

JFTOT (ASTM D3241) for deposit tendency, RPVOT (ASTM D2272), foam (ASTM D892), copper corrosion (ASTM D130), air release (ASTM D3427).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3806

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3807

|

Premium antioxidant

|

0.05 – 1.0

|

Industrial gearboxes face high loads, water ingress, and particulate contamination; additive resilience is critical for long drains and reliability.

Sulfur–phosphorus EP, AW boosters (including phosphorus/boron chemistries), antioxidants, demulsifiers, anti-foam, corrosion inhibitors/metal deactivators.

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3239

|

Copper Deactivator

|

0.02 – 0.05

|

|

PX 3237

|

Silver Deactivator

|

0.02 – 0.05

|

|

PX 3841

|

Anti-foamant

|

0.05 – 0.30

|

|

PX 3849

|

Extreme Pressure/Antiwear

|

0.1 – 0.4

|

|

PX 3846

|

Extreme Pressure/Antiwear

|

0.1 – 0.4

|

|

PX 3862

|

Corrosion Passivator

|

0.1 – 0.5

|

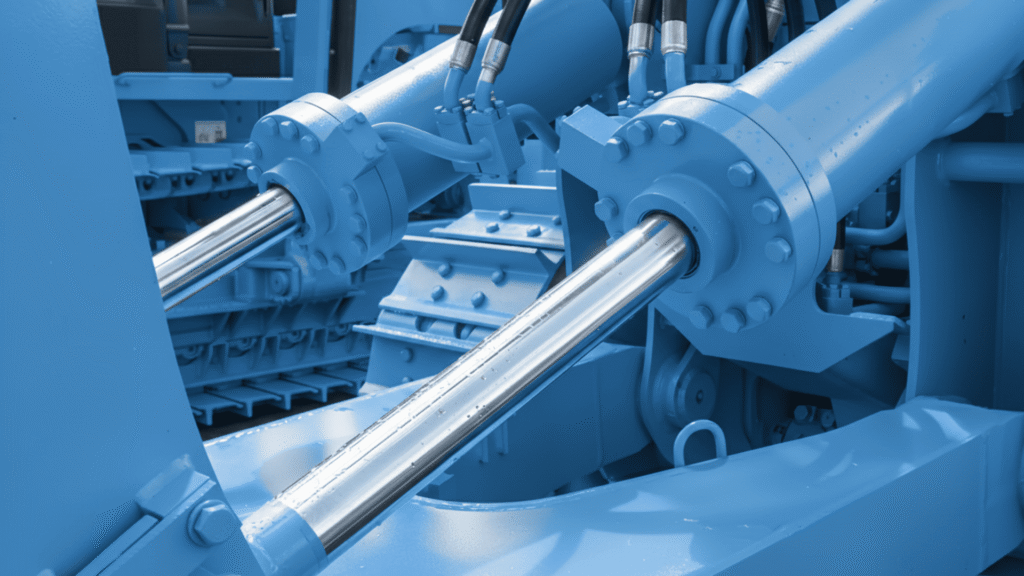

Hydraulic systems depend on precise valve clearances and pump protection; varnish, aeration, and wear rapidly degrade control accuracy and efficiency.

AW packages (zinc or ashless), antioxidants, anti-foam, rust inhibitors, demulsifiers, metal deactivators; cleanliness/varnish-control additives as needed.

Vane pump wear (ASTM D2882), oxidation life (TOST ASTM D943), foam (ASTM D892), air release (ASTM D3427), demulsibility (ASTM D1401), filterability (ISO 13357), rust (ASTM D665).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3239

|

Copper Deactivator

|

0.02 – 0.05

|

|

PX 3827

|

Silver Deactivator

|

0.02 – 0.05

|

|

PX 3806

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3807

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3843

|

Demulsifier & Defoamant

|

0.05 – 0.30

|

|

PX 4005

|

Dispersant

|

1.0 – 3.0

|

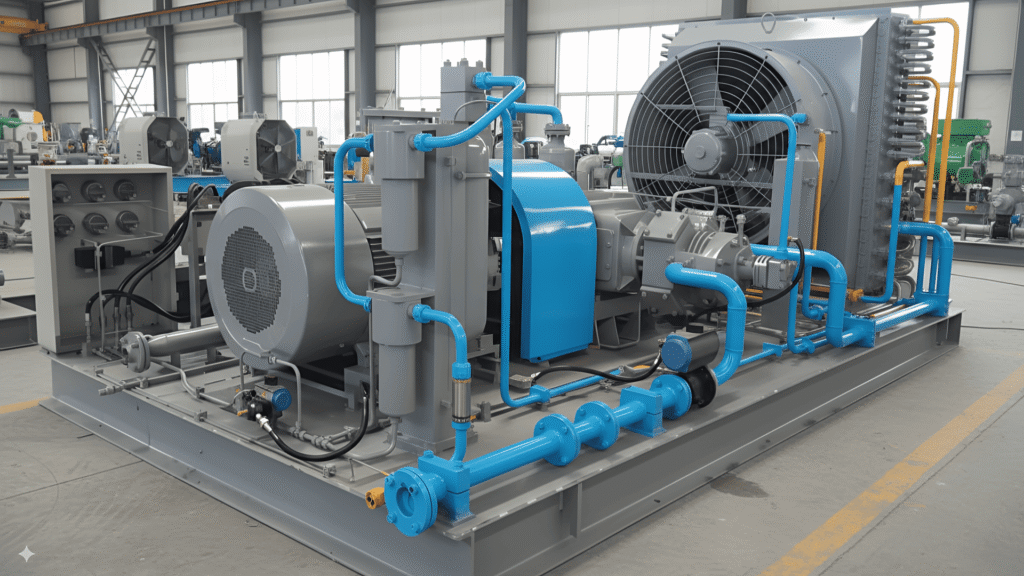

Rotary screw, reciprocating, and centrifugal compressors generate significant heat and air–oil interfacial area, promoting oxidation and deposit formation.

Antioxidants (amine/phenolic), AW agents where required, anti-foam, rust/corrosion inhibitors, metal deactivators; demulsifiers for water separation.

RPVOT (ASTM D2272), TOST (ASTM D943) for mineral systems, foam (ASTM D892), air release (ASTM D3427), rust (ASTM D665), deposit tendency (varnish/patch colorimetry).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3811

|

Oxidation Inhibitor

|

1.0 – 4.0

|

|

PX 3806

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3807

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3843

|

Demulsifier & Defoamant

|

0.05 – 0.30

|

|

PX 4005

|

Dispersant

|

1.0 – 3.0

|

Machine tool slideways require low stick–slip and predictable friction to preserve positioning accuracy under mixed lubrication with coolant contamination.

Friction modifiers (boundary-layer control), AW/EP, tackifiers for adhesion, corrosion inhibitors, demulsifiers and anti-foam tailored for coolant environments.

OEM slideway friction/stick–slip evaluations (e.g., Cincinnati Machine), demulsibility (ASTM D1401), rust (ASTM D665), foam (ASTM D892).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3845

|

Extreme Pressure/Antiwear

|

0.25 – 1.25

|

|

PX 3863

|

Corrosion Passivator

|

0.25 – 1.25

|

Large circulating systems (paper machines, turbines, bearings) demand long-life oxidation stability, rapid air release, and water shedding to sustain film thickness and cleanliness.

Antioxidants, rust inhibitors, demulsifiers, anti-foam; metal deactivators where copper alloys are present.

TOST (ASTM D943), RPVOT (ASTM D2272), air release (ASTM D3427), foam (ASTM D892), demulsibility (ASTM D1401), rust (ASTM D665).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3239

|

Copper Deactivator

|

0.02 – 0.05

|

|

PX 3827

|

Silver Deactivator

|

0.02 – 0.05

|

|

PX 3806

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3807

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3863

|

Corrosion Passivator

|

0.25 – 1.0

|

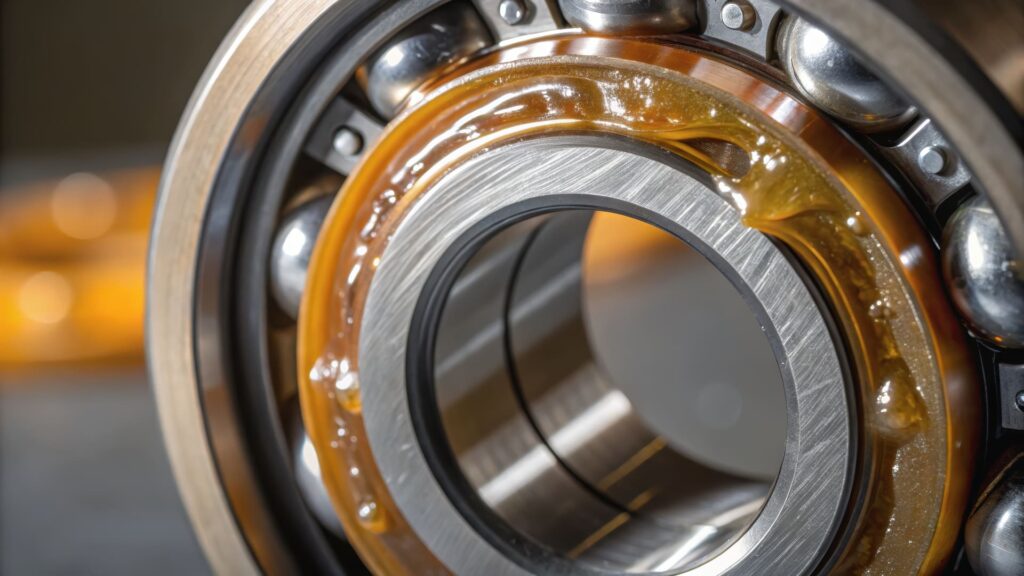

Greases must retain structure while providing EP/antiwear protection and corrosion resistance under contamination, vibration, and wide temperature ranges.

EP (sulfur–phosphorus, solid lubricants where appropriate), AW, antioxidants, rust/corrosion inhibitors, tackifiers, anti-foam; metal deactivators for copper-bearing components.

4-ball wear/EP (ASTM D2266/D2596), copper corrosion (ASTM D4048), water washout (ASTM D1264), dropping point (ASTM D2265), EMCOR rust (ISO 11007).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3239

|

Copper Deactivator

|

0.02 – 0.05

|

|

PX 3827

|

Silver Deactivator

|

0.02 – 0.05

|

|

PX 3849

|

Extreme Pressure/Antiwear

|

0.2 – 1.0

|

|

PX 3846

|

Extreme Pressure/Antiwear

|

0.2 – 1.0

|

|

PX 3861

|

Rust inhibitor

|

0.5 – 1.5

|

|

PX 3864

|

Rust inhibitor

|

0.25 – 1 1.5

|

|

PX 3865

|

Rust inhibitor

|

0.5 – 1.5

|

|

PX 3871

|

Friction modifier Grease Thickener

|

0.5 – 1.5

|

|

PX 3872

|

Friction modifier Grease Thickener

|

0.5 – 1.5

|

|

PX 3822

|

Dispersant Detergent

|

1.0 – 5.0

|

|

PX 4005

|

Dispersant

|

1.0 – 5.0

|

Severe boundary conditions at the tool–workpiece interface generate heat and adhesive wear; lubricity and EP chemistry are needed to prevent welding and extend tool life.

Friction modifiers/ester lubricity agents, sulfurized/phosphorus EP chemistries (chlorinated chemistries are often restricted), corrosion inhibitors, defoamers, biocide packages for waterborne systems.

Falex pin & vee block (ASTM D3233), 4-ball EP (ASTM D2783), tapping torque, foam (ASTM D892), copper strip corrosion (ASTM D130), staining tests per OEM/customer methods.

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3239

|

Copper Deactivator

|

0.02 – 0.05

|

|

PX 3827

|

Silver Deactivator

|

0.02 – 0.05

|

|

PX 3812

|

Friction Modifier

|

1.0 – 3.0

|

|

PX 3823

|

Dispersant/Detergent

|

dosage not specified

|

|

PX 3830

|

Emulsifier

|

dosage not specified

|

|

PX 3861

|

Rust inhibitor

|

0.05 – 1.0

|

|

PX 3864

|

Rust inhibitor

|

0.05 – 1.0

|

|

PX 3822

|

Dispersant Detergent

|

1.0 – 5.0

|

Drawing, stamping, rolling, and forging impose extreme pressures and sliding. Boundary-lubrication additives are essential to prevent scoring and achieve target draw ratios.

Sulfurized/phosphorus EP agents, polymeric/ester lubricity improvers, solid lubricants where applicable, corrosion inhibitors, emulsifiers for water-dilutable systems.

Cup drawing/limiting draw ratio, 4-ball EP/wear (ASTM D2783/D4172), Falex (ASTM D3233), staining/corrosion per substrate, residue/cleanability evaluations.

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3239

|

Copper Deactivator

|

0.02 – 0.05

|

|

PX 3827

|

Silver Deactivator

|

0.02 – 0.05

|

|

PX 3823

|

Dispersant/Detergent

|

dosage not specified

|

|

PX 3830

|

Emulsifier

|

dosage not specified

|

|

PX 3861

|

Rust inhibitor

|

0.05 – 1.0

|

|

PX 3864

|

Rust inhibitor

|

0.05 – 1.0

|

|

PX 3822

|

Dispersant Detergent

|

1.0 – 5.0

|

Our consultants are ready to help you maximize performance with the right catalyst and performance additives solution.