As regulatory pressure mounts and the demand for sustainable formulations intensifies, formulators across industries are reevaluating the role of organotin catalysts in their products. While organotin compounds once served as go-to solutions for catalysis and crosslinking in silicone sealants, polyurethane systems, and esterification reactions, their future is increasingly uncertain. Fortunately, high-performance alternatives—like organo-titanates and zirconates—are ready to meet modern performance and compliance demands.

In this article, we examine the compelling reasons why replacing organotin compounds with organotitanates is important, not just for compliance, but also for performance, safety, and sustainability.

Environmental and Ecological Impact

Organo-tin compounds, particularly tributyltin (TBT) and dibutyltin (DBT), are well-known marine pollutants. These chemicals are persistent in aquatic environments, bioaccumulate in marine life, and have been shown to cause severe disruptions in marine ecosystems. Research published in Environment International has linked organotin exposure to reproductive abnormalities in fish and mollusks, leading many countries to ban their use in antifouling paints and related applications.

Organo-titanates, by contrast, are far less ecotoxic and more environmentally degradable. Their lower bioaccumulation potential makes them a safer choice for products likely to enter aquatic or terrestrial ecosystems.

Human Health and Workplace Safety

The health risks associated with organotin exposure are equally concerning. The World Health Organization has classified several organotin compounds as immunotoxic, neurotoxic, and potential endocrine disruptors. These substances can be harmful even at low exposure levels, posing occupational risks during manufacturing and application.

Organo-titanates offer a significantly safer alternative. With lower toxicity profiles and less hazardous decomposition products, titanate catalysts reduce worker exposure risks and simplify safety protocols in production environments.

Compliance with Global Regulations

The regulatory landscape is evolving rapidly:

- The EU REACH Regulation imposes strict limits on the use of organotin compounds in consumer and industrial products.

- The RoHS Directive restricts the use of organotin compounds in electronics.

- In the U.S., the EPA and OSHA are scrutinizing organotin applications under TSCA and workplace hazard laws.

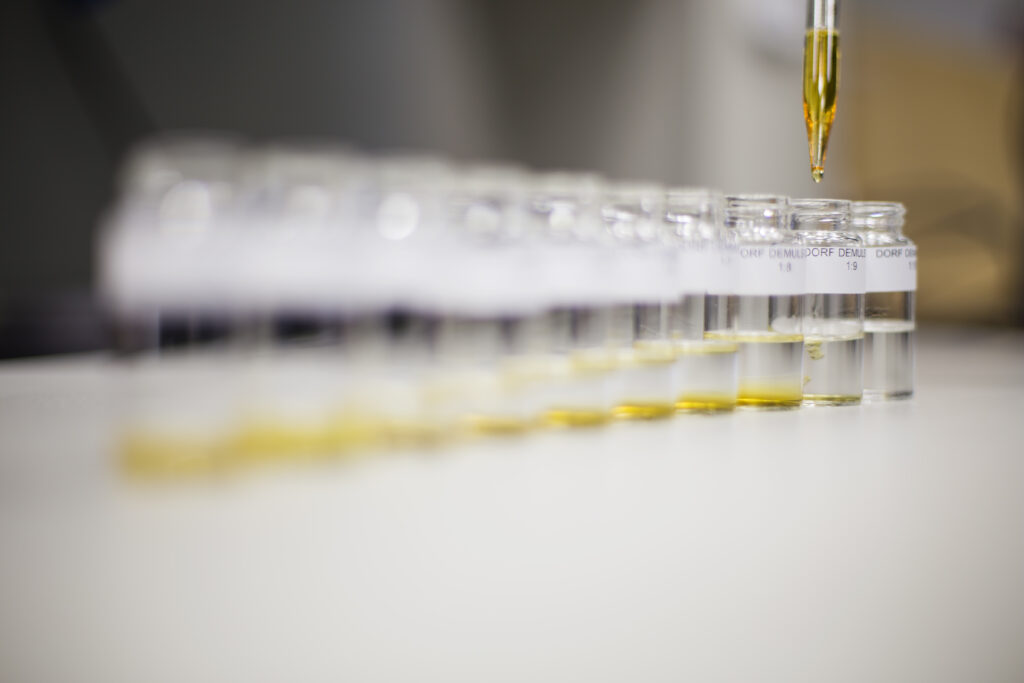

These and other global frameworks are pushing formulators toward metal-organic alternatives that can maintain performance while ensuring compliance. Organo-titanates and zirconates from companies like Dorf Ketal have emerged as drop-in solutions that meet REACH, RoHS, and food-contact safety standards without compromising reactivity.

Performance Advantages for Formulators

While many assume that moving away from organotin means sacrificing performance, titanate-based catalysts often improve it:

- Crosslinking and Adhesion: Titanates form covalent or coordinate bonds with functional groups on polymers and substrates, delivering superior adhesion and durability in coatings, inks, and sealants.

- Reactivity Control: With customizable reactivity profiles, titanates provide better control over open time, green strength, and curing rates—essential for high-throughput manufacturing.

- Versatility: Organo-titanates are compatible with a wide range of systems, including waterborne, solvent-based, and 100% solids formulations.

Dorf Ketal’s Tyzor® line, for example, has proven success in replacing organotin catalysts in polyurethane dispersions, RTV silicones, PET polymerization, and esterification reactions.

Sustainability and Market Differentiation

Consumers and end-users are increasingly looking for low-toxicity, environmentally conscious products. By moving to safer, tin-free systems, manufacturers can:

- Enhance product labels with “heavy metal-free” or “eco-friendly” claims.

- Align with corporate sustainability and ESG targets.

- Future-proof their portfolios against evolving global legislation.

In an industry where innovation and compliance must go hand in hand, the ability to offer safer chemistries without sacrificing quality is a strategic advantage.

Conclusion

The science is clear, the regulations are tightening, and the technology is ready. Organo-titanates, such as those in Dorf Ketal’s Tyzor® and Unilink® lines, provide a proven, high-performance alternative to organotin compounds across coatings, adhesives, sealants, polymers, and specialty chemical applications.

Whether you’re developing a next-generation sealant, a food-contact-safe packaging adhesive, or a low-VOC industrial coating, replacing organotin with organo-titanates isn’t just a compliance checkbox—it’s an opportunity to lead in safety, sustainability, and innovation.