Applications Applications Applications Applications

- Home

- /

- Applications

- /

- Applications

- /

- Lube Additives

- /

- Industrial Gear Oils

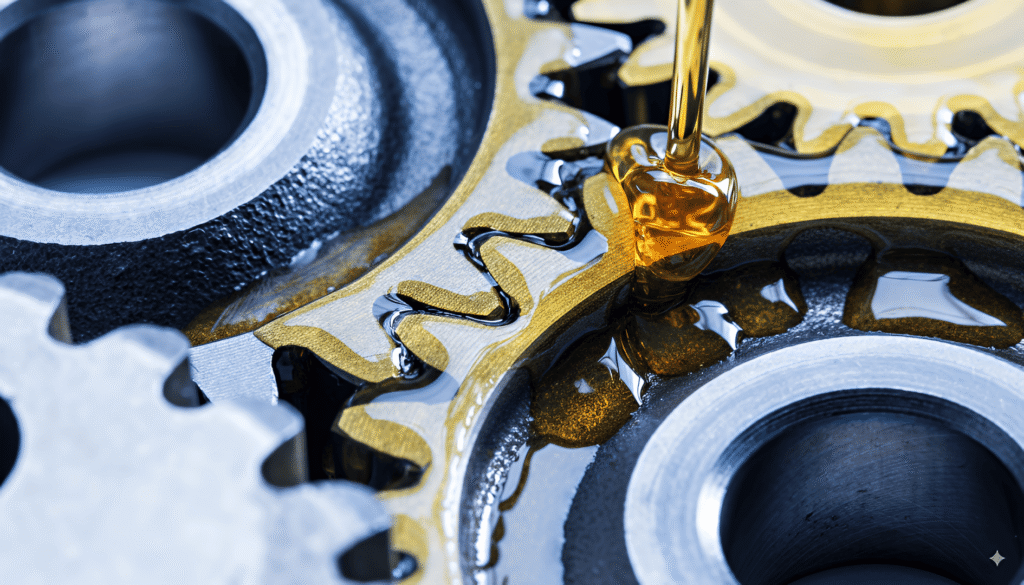

Lube Additives for Industrial Gear Oils

Overview:

Industrial gearboxes face high loads, water ingress, and particulate contamination; additive resilience is critical for long drains and reliability.

Why an additive package is required:

- Deliver EP/antiwear protection against scuffing and micropitting.

- Provide rust and yellow-metal protection in wet or corrosive environments.

- Ensure foam control, air release, and water separation for stable film thickness and cooling.

Typical additive families employed:

Sulfur–phosphorus EP, AW boosters (including phosphorus/boron chemistries), antioxidants, demulsifiers, anti-foam, corrosion inhibitors/metal deactivators.

Indicative performance tests:

FZG (ISO 14635), demulsibility (ASTM D1401), foam (ASTM D892), rust (ASTM D665 A/B), copper corrosion (ASTM D130), micropitting (ISO 15144).

Recommended PX Products

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3239

|

Copper Deactivator

|

0.02 – 0.05

|

|

PX 3237

|

Silver Deactivator

|

0.02 – 0.05

|

|

PX 3841

|

Anti-foamant

|

0.05 – 0.30

|

|

PX 3849

|

Extreme Pressure/Antiwear

|

0.1 – 0.4

|

|

PX 3846

|

Extreme Pressure/Antiwear

|

0.1 – 0.4

|

|

PX 3862

|

Corrosion Passivator

|

0.1 – 0.5

|

CONTACT US

Our consultants are ready to help you maximize performance with the right catalyst and performance additives solution.