Applications Applications Applications Applications

- Home

- /

- Applications

- /

- Applications

- /

- Lube Additives

- /

- Greases

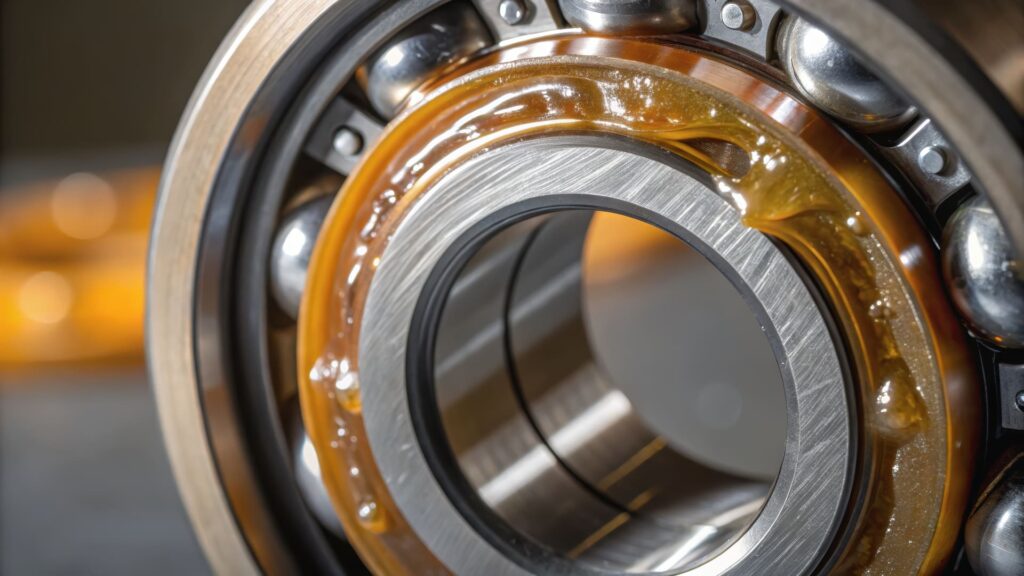

Lube Additives for Greases

Overview:

Greases must retain structure while providing EP/antiwear protection and corrosion resistance under contamination, vibration, and wide temperature ranges.

Why an additive package is required:

- Deliver EP/antiwear performance under shock and oscillatory motion.

- Resist oxidation of the base oil and protect against rust in wet environments.

- Enhance mechanical stability and adhesion to reduce leakage and washout.

Typical additive families employed:

EP (sulfur–phosphorus, solid lubricants where appropriate), AW, antioxidants, rust/corrosion inhibitors, tackifiers, anti-foam; metal deactivators for copper-bearing components.

Indicative performance tests:

4-ball wear/EP (ASTM D2266/D2596), copper corrosion (ASTM D4048), water washout (ASTM D1264), dropping point (ASTM D2265), EMCOR rust (ISO 11007).

Recommended PX Products

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3239

|

Copper Deactivator

|

0.02 – 0.05

|

|

PX 3827

|

Silver Deactivator

|

0.02 – 0.05

|

|

PX 3849

|

Extreme Pressure/Antiwear

|

0.2 – 1.0

|

|

PX 3846

|

Extreme Pressure/Antiwear

|

0.2 – 1.0

|

|

PX 3861

|

Rust inhibitor

|

0.5 – 1.5

|

|

PX 3864

|

Rust inhibitor

|

0.25 – 1 1.5

|

|

PX 3865

|

Rust inhibitor

|

0.5 – 1.5

|

|

PX 3871

|

Friction modifier Grease Thickener

|

0.5 – 1.5

|

|

PX 3872

|

Friction modifier Grease Thickener

|

0.5 – 1.5

|

|

PX 3822

|

Dispersant Detergent

|

1.0 – 5.0

|

|

PX 4005

|

Dispersant

|

1.0 – 5.0

|

CONTACT US

Our consultants are ready to help you maximize performance with the right catalyst and performance additives solution.