Applications Applications Applications Applications

- Home

- /

- Applications

- /

- Applications

- /

- Lube Additives

- /

- Hydraulic Fluids

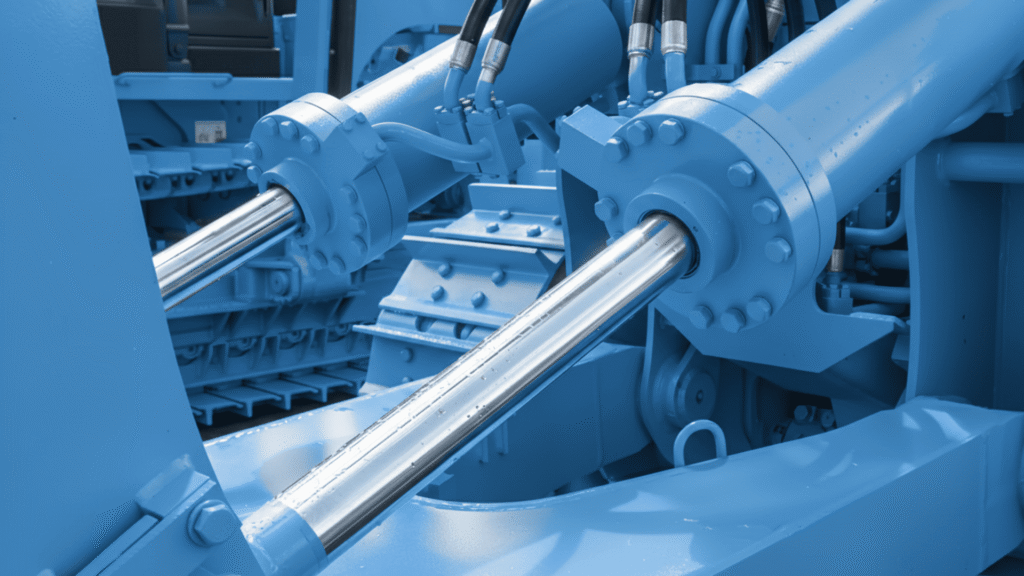

Lube Additives for Hydraulic Fluids

Overview:

Hydraulic systems depend on precise valve clearances and pump protection; varnish, aeration, and wear rapidly degrade control accuracy and efficiency.

Why an additive package is required:

- Provide AW protection (vane/piston/gear pumps) and reduce wear in boundary contacts.

- Inhibit oxidation and varnish to maintain servo-valve responsiveness.

- Control foam and air release; ensure water separation and filterability.

Typical additive families employed:

AW packages (zinc or ashless), antioxidants, anti-foam, rust inhibitors, demulsifiers, metal deactivators; cleanliness/varnish-control additives as needed.

Indicative performance tests:

Vane pump wear (ASTM D2882), oxidation life (TOST ASTM D943), foam (ASTM D892), air release (ASTM D3427), demulsibility (ASTM D1401), filterability (ISO 13357), rust (ASTM D665).

Recommended PX Products

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3239

|

Copper Deactivator

|

0.02 – 0.05

|

|

PX 3827

|

Silver Deactivator

|

0.02 – 0.05

|

|

PX 3806

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3807

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3843

|

Demulsifier & Defoamant

|

0.05 – 0.30

|

|

PX 4005

|

Dispersant

|

1.0 – 3.0

|

CONTACT US

Our consultants are ready to help you maximize performance with the right catalyst and performance additives solution.