From advanced catalysts to high-performance additives, Dorf Ketal delivers solutions that power efficiency, sustainability, and reliability. Our trusted technologies—Tyzor®, Unilink®, and Clearlink®—enable breakthroughs in coatings, polymerization, adhesion, etc.

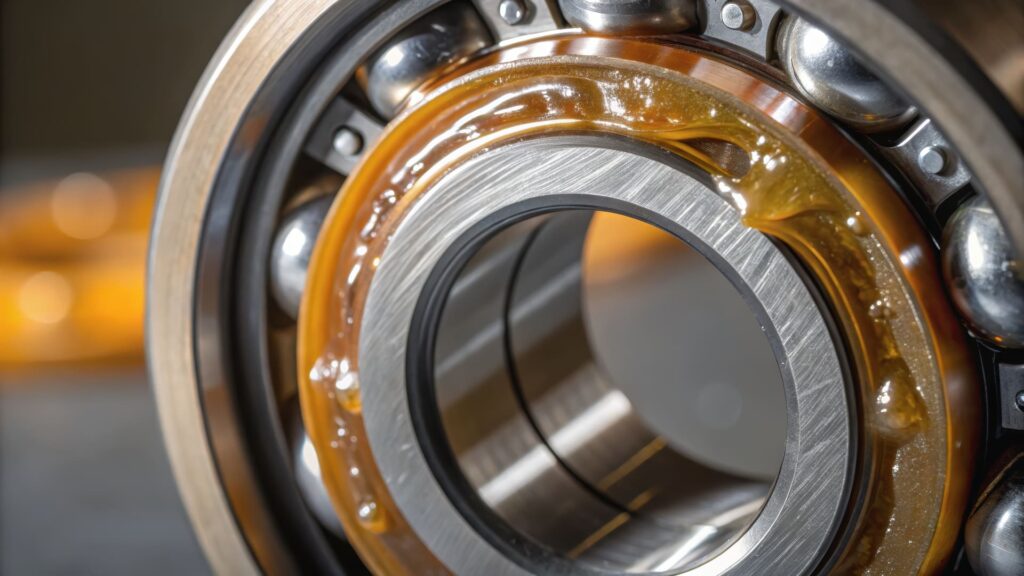

Now, with the PX SERIES line of Lube Additives, we bring unmatched protection and performance to the lubrication industry, ensuring longer equipment life and optimized operations.

Titanate-based catalysts from Dorf Ketal, specifically the Tyzor® line, are widely recognized in the printing ink industry for enhancing performance and enabling formulation flexibility in demanding applications such as flexible packaging. These inks—commonly used in gravure and flexographic printing—require not only excellent adhesion to low-energy substrates like polypropylene (PP), polyethylene (PE), and metal foils but also superior resistance to solvents, water, and heat. Tyzor® catalysts are a critical enabler in meeting these requirements.

At the core of this performance enhancement is the ability of organotitanium compounds to act as multifunctional additives—serving as adhesion promoters, crosslinking agents, and surface modifiers. When incorporated into NC-based (nitrocellulose) or polyurethane resins, Tyzor® additives significantly improve the cohesion of the ink film and the bonding to difficult substrates such as corona-treated OPP and PET. Laboratory testing using standardized adhesion protocols, including the Tesa tape test, has demonstrated that formulations containing Tyzor® AA-75 or similar chelates outperform untreated systems by a wide margin, even after short drying periods at elevated temperatures.

|

Subcategory/Type

|

Primary Products

|

|---|---|

|

All

|

Tyzor AA, Tyzor AA-105, Tyzor AA-65, Tyzor AA-75, Tyzor GBA, Tyzor IAM, Tyzor LA, Tyzor TE, Tyzor ZEC

|

Paints and coatings serve a dual purpose in industrial and commercial applications: protecting substrates from environmental degradation and enhancing visual and functional properties such as color, gloss, corrosion resistance, and chemical durability. Dorf Ketal’s Tyzor® catalysts provide a powerful set of tools for formulators seeking to improve the performance of waterborne, solvent-based, and 100% solids coating systems.

Tyzor® organotitanates, and organozirconates are highly effective as crosslinking agents, adhesion promoters, and reactive modifiers. They function by interacting with functional groups in the binder resins—such as hydroxyl, carboxyl, or amine groups—in systems based on polyurethane, epoxy, or acrylic chemistries. This leads to denser, more chemically resistant polymer networks with superior film integrity.

In solvent-based coatings, Tyzor® catalysts enhance curing, reduce dry times, and increase compatibility with inorganic pigments and fillers. This results in improved rheology, better pigment dispersion, and enhanced mechanical properties such as scratch resistance and hardness. These benefits are particularly valuable in protective coatings for metal substrates, including machinery, automotive components, and industrial equipment.

|

Subcategory/Type

|

Primary Products

|

|---|---|

|

Solvent-Based

|

Tyzor 9000, Tyzor AA, Tyzor AA-105, Tyzor AA-65, Tyzor AA-75, Tyzor BTP, Tyzor GLA, Tyzor OGT, Tyzor TE, Tyzor TEAZ, Tyzor TOT, Clearlink 1000, Clearlink 1080, Unilink 4100, Unilink 4200, Unilink 4230

|

|

Water-Based

|

Tyzor 217, Tyzor LA, Unilink 1030, Unilink 2130, Unilink 2500

|

|

Wire and Enamel

|

Tyzor TnBT, Tyzor TPT, Tyzor TPT-20B

|

|

Titanium based

|

Unilink 2000 Series

|

|

Zirconion based

|

Unilink 1000 Series

|

Metal coatings serve as critical protection and performance layers in industries ranging from automotive and aerospace to construction and electronics. Dorf Ketal’s Tyzor® catalysts play a vital role in enhancing the performance of these coatings by acting as both adhesion promoters and functional catalysts. These titanate and zirconate compounds are particularly effective in corrosion-resistant primers, coil coatings, and conductive layers, where metal-to-coating interface durability is essential.

One of the most important roles of Tyzor® catalysts in metal coatings is enhancing corrosion resistance. By introducing organotitanate molecules into primer formulations—especially those containing sacrificial metals like zinc—Tyzor® compounds contribute to forming a tightly bonded, chemically resistant layer that prevents oxidation and surface degradation. This is particularly valuable in thin-film coatings where traditional pigment volume concentration is insufficient to ensure long-term protection.

The unique chemistry of Tyzor® compounds allows them to act as adhesion promoters and inorganic network formers. When applied to metal substrates, especially those exposed to harsh environmental conditions (e.g., automotive fasteners, clamps, and chassis components), titanates can form a reactive TiO₂ layer that chemically binds to the metal surface. This layer serves as a foundation for subsequent coating layers, improves mechanical adhesion, and prevents delamination under thermal and mechanical stress.

|

Subcategory/Type

|

Primary Products

|

|---|---|

|

Metal Parts, Water-Based

|

Tyzor 217, Tyzor LA, Unilink 2130, Unilink 2500

|

|

Metal Parts, Solvent-Based

|

Tyzor 9000, Tyzor AA, Tyzor AA-105, Tyzor AA-65, Tyzor AA-75, Tyzor D-140, Tyzor BTP, Tyzor CLA, Tyzor EHTAA (XL-100), Tyzor ET, Tyzor NBZ, Tyzor NPZ, Tyzor TE, Tyzor TEAZ, Tyzor TnBT, Tyzor TOT, Tyzor TPT, Tyzor TPT-20B, Tyzor ZT-120, Clearlink 1000, Clearlink 1080, Unilink 4100, Unilink 4200, Unilink 4230

|

Dorf Ketal has the industry’s broadest portfolio of organo-titanate cross-linkers and additives for sealants and adhesives. We are actively developing new products as organo-tin alternatives. All with the singular goal of providing products that meet our customer’s needs for cross-linkers, catalysts, moisture scavengers and modulus modifiers.

Dorf Ketal’s broad product line of titanate and zirconate organometallics and amine chain extenders has generated measurable customer value in the global CASE market for more than three decades and we continue to improve the performance of our customers’ products and synthesize new polymer resins today. We are committed to providing sealant and adhesive producers with complete range of high quality products, good service and competitive prices.

|

Product

|

Sealant Type

|

Segment

|

Product Attributes

|

|---|---|---|---|

|

Tyzor 722

|

• Silicone (RTV-1)

|

• Construction

|

• Cure Time: 10 min

• Tack Free Time, minutes: 45 • Relative Adhesion: 0.8 • Skin Formation Time: 10-60 min • Other: Freezes at 0°C |

|

Tyzor 726

|

• Silicone (RTV-1)

• Acrylic |

• Industrial

• Electronic |

• Cure Time: <5 min

• Tack Free Time, minutes: 2-5 • Relative Adhesion: 1 • Skin Formation Time: 5-30 min • Other: Freezes at 25°C |

|

Tyzor 728

|

• Silicone (RTV-1)

• Silanol end-cappe • Acrylic |

• Construtction

• Industrial • Automotive • Electronic |

• Cure Time: <5min

• Tack Free Time, minutes: 5-7 • Relative Adhesion: 0.92 • Skin Formation Time: 5-30 min • Other: Freezes at 10C |

|

Tyzor 795

|

• Silicone (RTV-1)

• Polysiloxane • STP, MS Polymer |

• Automotive

|

• Cure Time: 12-24 h

• Tack Free Time, minutes: 10-30 • Relative Adhesion: 0.95 • Skin Formation Time: 10-30 min • Other: Freezes at -30C |

|

Tyzor IBAY

|

• Silicone (RTV-1)

• Polysiloxane • Silanol end-capped • Acrylic • Polyurethane |

• Construction

• Industrial • Automotive |

• Cure Time: 24 h

• Tack Free Time, minutes: 60-90 • Relative Adhesion: 0.6 • Skin Formation Time: 10-30 min • Other: Freezes at -35C |

|

Tyzor KE-6

|

• Silicone (RTV-1)

• Polysiloxane • STP, MS Polymer • Acrylic |

• Construction

• Industrial • Automotive |

• Cure Time: 12-24 h

• Tack Free Time, minutes: 10-30 • Relative Adhesion: 0.9 • Skin Formation Time: 10-30 min • Other: Freezes at -35C |

|

Tyzor PITA

|

• Silicone (RTV-1)

• Acrylic |

• Industrial

• Eletronic |

• Cure Time: <5min

• Tack Free Time, minutes: 2-5 • Relative Adhesion: 1 • Skin Formation Time: 10-30 min • Other: Freezes at 25C |

|

Tyzor PITA-SM

|

• Silicone (RTV-1)

• Silanol end-capped • Acrylic |

• Industrial

• Eletronic |

• Cure Time: <5min

• Tack Free Time, minutes: 5-7 • Relative Adhesion: 0.92 • Skin Formation Time: 5-30 min • Other: Freezes at 10C |

|

Tyzor 9000

|

• Polysiloxane

• Epoxy • Acrylic • Polyurethane |

• Construtction

• Industrial • Automotive • Electronic |

• Cure Time: 3-5min

• Tack Free Time, minutes: 1-2 • Relative Adhesion: 0.25 • Skin Formation Time: 3-5 min • Other: Freezes at -40C |

Polyethylene Terephthalate (PET) is one of the world’s most widely produced thermoplastic polyesters, used in applications ranging from beverage bottles and food containers to textile fibers and engineering resins. In the production of PET, the choice of catalyst plays a critical role in determining the efficiency of the polymerization process and the final product’s physical and mechanical properties.

Dorf Ketal‘s ACtivate™ and Tyzor® titanate catalysts offer significant advantages over traditional metal-based catalysts such as antimony trioxide or manganese acetate. These organotitanium compounds act as highly effective esterification and polycondensation catalysts, enabling manufacturers to achieve high molecular weight PET with lower color formation, faster reaction rates, and improved downstream processability.

In the melt phase of PET production, ACtivate™ and Tyzor® catalysts promote the transesterification of dimethyl terephthalate (DMT) or the direct esterification of terephthalic acid (PTA) with ethylene glycol (EG). This reaction forms oligomers that are subsequently polycondensed into high-molecular-weight PET. The use of ACtivate™ and Tyzor® catalysts enables efficient conversion with reduced side reactions, such as olefin formation, which can lead to color bodies or undesirable byproducts.

|

Subcategory/Type

|

Primary Products

|

|---|---|

|

PBT, PPT, Others

|

Tyzor D-140, Tyzor TnBT, Tyzor TPT, Tyzor TPT-20B, ACtivate 422, ACtivate 436

|

|

Polyolefin

|

Tyzor D-140, Tyzor NPT, Tyzor TnBT, Tyzor TPT, Tyzor TPT-20B, Tyzor ZT-120

|

|

Polycarbonate

|

Tyzor TnBT, Tyzor TPT, Tyzor TPT-20B

|

|

PET

|

Tyzor 64, ACtivate 422, ACtivate 436

|

|

Polyol/Polyester

|

Tyzor TE, Tyzor 9000, Tyzor TnBT

|

Tyzor® organic titanates and zirconates are highly effective Lewis acid catalysts for esterification and transesterification reactions. Developed and optimized over five decades, these catalysts are widely used in producing acrylate esters, plasticizers (e.g., phthalates), and polyester resins such as PET and PBT.

In transesterification, Tyzor® alkoxide-based catalysts—such as Tyzor® TPT, TPT-20B, and TnBT—are noted for their high reactivity and fast conversion rates under anhydrous conditions. These catalysts promote the efficient exchange of ester groups between molecules with minimal byproduct formation. As long as water is excluded, the reaction proceeds cleanly, making these catalysts ideal for producing high-purity esters in continuous or batch processing.

Tyzor® catalysts differ in their moisture sensitivity. Lower molecular weight alkoxides are highly reactive but must be carefully handled in moisture-free environments. For systems where some exposure to water is unavoidable, higher molecular weight alkoxides such as Tyzor® TOT and stable chelates like Tyzor® TE provide enhanced hydrolytic stability. These grades may require slightly higher temperatures and reaction times but are compatible with a broader range of process conditions and raw materials.

|

Subcategory/Type

|

Primary Products

|

|---|---|

|

Plasticizers

|

Tyzor D-140, Tyzor NPT, Tyzor TnBT, Tyzor TOT, Tyzor TPT, Tyzor TPT-20B

|

|

Acrylic Esters

|

Tyzor 75, Tyzor ET, Tyzor NPT, Tyzor TnBT, Tyzor TOT, Tyzor TPT, Tyzor TPT-20B

|

|

All Other

|

Tyzor D-140, Tyzor BTP, Tyzor ET, Tyzor LA, Tyzor NPT, Tyzor OGT, Tyzor TE, Tyzor TEAZ, Tyzor TnBT, Tyzor TOT, Tyzor TPT, Tyzor TPT-20B

|

Glass is used in a broad array of structural, decorative, and high-tech applications. Its properties can be significantly enhanced by surface treatments designed to modify adhesion, optical behavior, resistance, and functionality. Tyzor® organic titanates and zirconates, developed by by Dorf Ketal, offer a high-performance solution for the surface treatment of glass. These compounds function as adhesion promoters, surface modifiers, and functional catalysts, improving durability and performance.

Tyzor® compounds apply to many forms of glass, including:

As adhesion promoters, Tyzor® materials improve bonding between glass substrates and coatings or polymer matrices. They can be applied as primers in pre-treatment steps or added directly to coating formulations. The result is a substantial enhancement in resistance to water, chemicals, and mechanical abrasion.

|

Subcategory/Type

|

Primary Products

|

|---|---|

|

All

|

Tyzor 9000, Tyzor ET, Tyzor GBA, Tyzor TnBT, Tyzor TOT, Tyzor TPT, Tyzor TPT-20B

|

Polyurea is an elastomer formed by the rapid reaction of isocyanates with polyamines. It cures extremely fast, without the need for catalysts, and develops excellent toughness, elongation, and chemical resistance.

Polyurea is synthesized by combining isocyanates (aromatic or aliphatic) with diamine curatives or chain extenders. The reaction is moisture tolerant and applied mainly through spray techniques.

|

Product

|

Function

|

Key Benefits

|

|---|---|---|

|

Clearlink® 1000

|

Aliphatic diamine chain extender

|

Tough, UV-stable polyurea; improved strength & heat resistance

|

|

Clearlink® 1080

|

Aliphatic diamine chain extender

|

Durable, UV-stable; low moisture sensitivity; slower reactivity

|

|

Unilink® Aromatic Diamines

|

Chain extender

|

Ambient cure; improved adhesion and finish

|

Polyurethanes are versatile polymers formed by the reaction of isocyanates with polyols, often modified by chain extenders and catalysts. They can be flexible, rigid, or elastomeric depending on formulation.

Polyurethanes are produced by combining diisocyanates (MDI, TDI, etc.) with polyether or polyester polyols. The use of catalysts and chain extenders controls the cure rate, mechanical properties, and processing window.

|

Product

|

Function

|

Key Benefits

|

|---|---|---|

|

Unilink® 1000 Series

|

Polyurethane catalyst

|

Fast cure, high productivity, tin replacement

|

|

Unilink® 2000 Series

|

Polyurethane catalyst

|

Delayed cure, mercury replacement, tailored properties

|

|

Clearlink® 1000/1080

|

Chain extender

|

Strength, UV stability, improved compatibility

|

|

Tyzor® 9000, AA series

|

Catalyst

|

Moderate to fast cure, environmentally responsible

|

Epoxies are thermosetting polymers formed by the reaction of epoxide groups with curing agents (amines, anhydrides, or organometallic compounds). They are known for strong adhesion, chemical resistance, and dimensional stability.

Epoxy resins are typically synthesized from bisphenol A (BPA) and epichlorohydrin. They are cured using hardeners or catalysts, which determine final mechanical and thermal properties.

|

Product

|

Function

|

Key Benefits

|

|---|---|---|

|

Tyzor® AA Series

|

Epoxy curing agent

|

Moderate to fast cure, resistant, color control

|

|

Tyzor® 9000

|

Epoxy curing agent

|

Fast cure, low color impact

|

Combustion-driven environments expose lubricants to high temperatures, fuel/soot contamination, and catalytic surfaces. Without robust additive systems, oxidation, sludge/varnish formation, wear, and acid build-up quickly compromise engine durability and fuel economy.

Antioxidants (amine/phenolic), AW/EP (e.g., ZDDP within phosphorus limits), detergents (overbased sulfonates/phenates), dispersants (succinimide/ester), friction modifiers (organic molybdenum/OFMs), anti-foam, corrosion/metal deactivators (triazoles), pour point depressants and VI improvers as needed.

Noack volatility (ASTM D5800), HTHS viscosity (ASTM D4683), CCS/MRV (ASTM D5293/D4684), TEOST (ASTM D6335), copper corrosion (ASTM D130), foam (ASTM D892), RPVOT (ASTM D2272) for oxidation screening, TBN/TAN (ASTM D2896/D664).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3823

|

Dispersant/Detergent

|

Dosage not specified

|

|

PX 3841

|

Anti-foamant

|

0.05 – 0.30

|

|

PX 3849

|

Extreme Pressure/Antiwear

|

0.5 – 1.0 Marine

|

|

PX 3847

|

Extreme Pressure/Antiwear

|

0.5 – 1.0 Marine

|

|

PX 3822

|

Dispersant Detergent

|

2.0 – 10.0

|

|

PX 4005

|

Dispersant

|

5.0 – 15.0

|

|

PX 4006

|

Dispersant + Lubricity

|

2.0 – 15.0

|

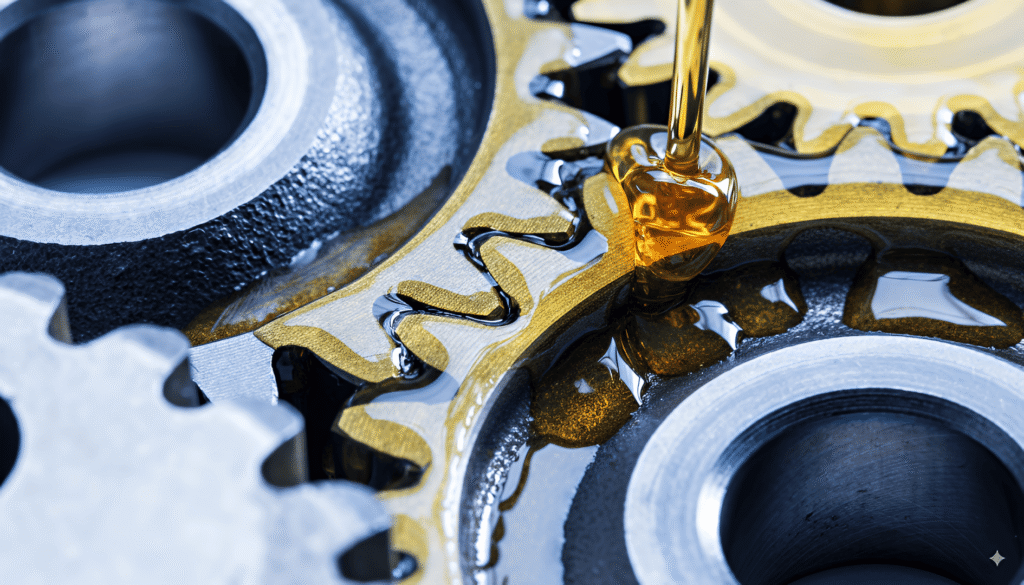

Hypoid and heavy-duty gear sets operate with high sliding and Hertzian contact stresses, demanding EP performance and thermal robustness to prevent scuffing, pitting, and micropitting.

Sulfur–phosphorus EP packages, AW agents, friction modifiers (for synchronized transmissions), antioxidants, anti-foam, corrosion inhibitors/metal deactivators, demulsifiers.

FZG scuffing/micropitting (ISO 14635/ISO 15144), 4-ball EP/wear (ASTM D2783/D4172), copper corrosion (ASTM D130), foam (ASTM D892), demulsibility (ASTM D1401).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3823

|

Dispersant/Detergent

|

0.5 – 2.0

|

|

PX 3825

|

Friction Modifier

|

0.1 – 1.5

|

|

PX 3841

|

Anti-foamant

|

0.05 – 0.30

|

|

PX 3849

|

Extreme Pressure/Antiwear

|

0.5 – 1.5

|

|

PX 3846

|

Extreme Pressure/Antiwear

|

0.5 – 1.5

|

|

PX 3862

|

Corrosion Passivator

|

0.1 – 0.5

|

|

PX 3871

|

Friction modifier Grease Thickener

|

0.3 – 1.5

|

|

PX 3872

|

Friction modifier Grease Thickener

|

0.3 – 1.5

|

|

PX 4005

|

Dispersant

|

1.0 – 2.0

|

|

PX 4006

|

Dispersant + Lubricity

|

1.0 – 2.0

|

Spark-ignited gas engines experience high oxidation and nitration with lean burn conditions; low-ash requirements protect combustion hardware and aftertreatment.

Antioxidants (high-temperature), low-/medium-ash detergents (overbased), ashless dispersants, AW, anti-foam, metal deactivators; gas-engine-specific detergency packages.

RPVOT (ASTM D2272), TBN/TAN (ASTM D2896/D664), FTIR nitration/oxidation, deposit tests (TEOST), copper corrosion (ASTM D130).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3811

|

Oxidation Inhibitor

|

1.0 – 4.0

|

|

PX 3806

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3807

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3841

|

Anti-foamant

|

0.05 – 0.30

|

|

PX 4005

|

Dispersant

|

2.0 – 10.0

|

|

PX 4006

|

Dispersant + Lubricity

|

2.0 – 10.0

|

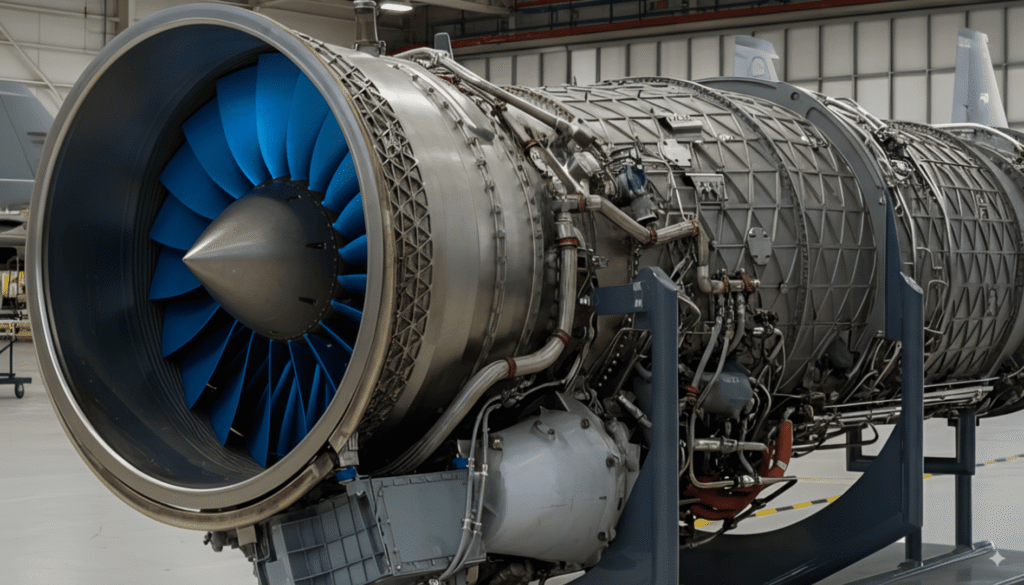

Aviation turbines (often ester-based fluids) require exceptional thermal/oxidative stability and deposit control under high bulk and skin temperatures.

High-performance antioxidants (amine/phenolic), metal deactivators (triazoles), anti-foam, rust/corrosion inhibitors; deposit-control synergists compatible with synthetic esters.

JFTOT (ASTM D3241) for deposit tendency, RPVOT (ASTM D2272), foam (ASTM D892), copper corrosion (ASTM D130), air release (ASTM D3427).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3806

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3807

|

Premium antioxidant

|

0.05 – 1.0

|

Industrial gearboxes face high loads, water ingress, and particulate contamination; additive resilience is critical for long drains and reliability.

Sulfur–phosphorus EP, AW boosters (including phosphorus/boron chemistries), antioxidants, demulsifiers, anti-foam, corrosion inhibitors/metal deactivators.

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3239

|

Copper Deactivator

|

0.02 – 0.05

|

|

PX 3237

|

Silver Deactivator

|

0.02 – 0.05

|

|

PX 3841

|

Anti-foamant

|

0.05 – 0.30

|

|

PX 3849

|

Extreme Pressure/Antiwear

|

0.1 – 0.4

|

|

PX 3846

|

Extreme Pressure/Antiwear

|

0.1 – 0.4

|

|

PX 3862

|

Corrosion Passivator

|

0.1 – 0.5

|

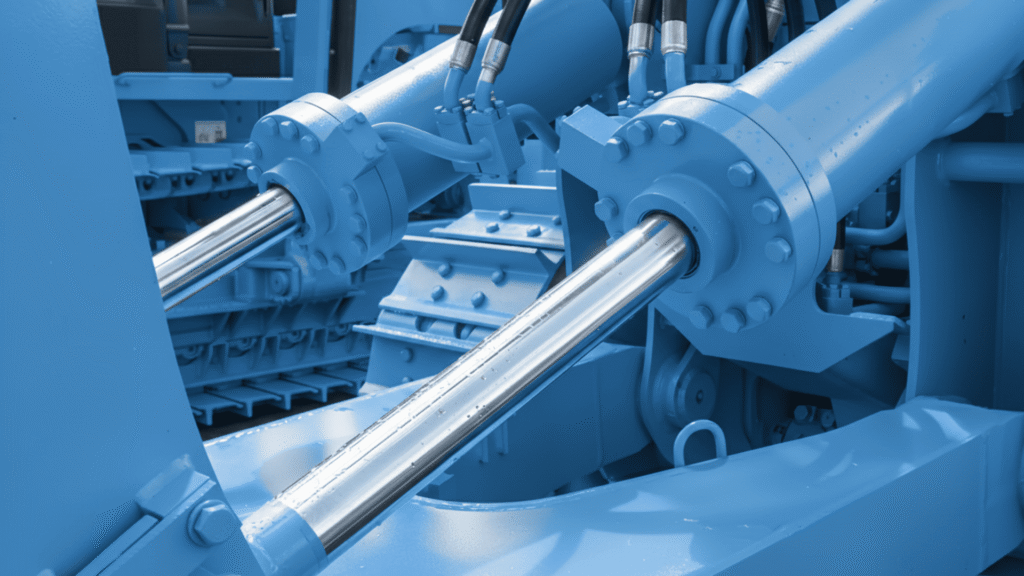

Hydraulic systems depend on precise valve clearances and pump protection; varnish, aeration, and wear rapidly degrade control accuracy and efficiency.

AW packages (zinc or ashless), antioxidants, anti-foam, rust inhibitors, demulsifiers, metal deactivators; cleanliness/varnish-control additives as needed.

Vane pump wear (ASTM D2882), oxidation life (TOST ASTM D943), foam (ASTM D892), air release (ASTM D3427), demulsibility (ASTM D1401), filterability (ISO 13357), rust (ASTM D665).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3239

|

Copper Deactivator

|

0.02 – 0.05

|

|

PX 3827

|

Silver Deactivator

|

0.02 – 0.05

|

|

PX 3806

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3807

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3843

|

Demulsifier & Defoamant

|

0.05 – 0.30

|

|

PX 4005

|

Dispersant

|

1.0 – 3.0

|

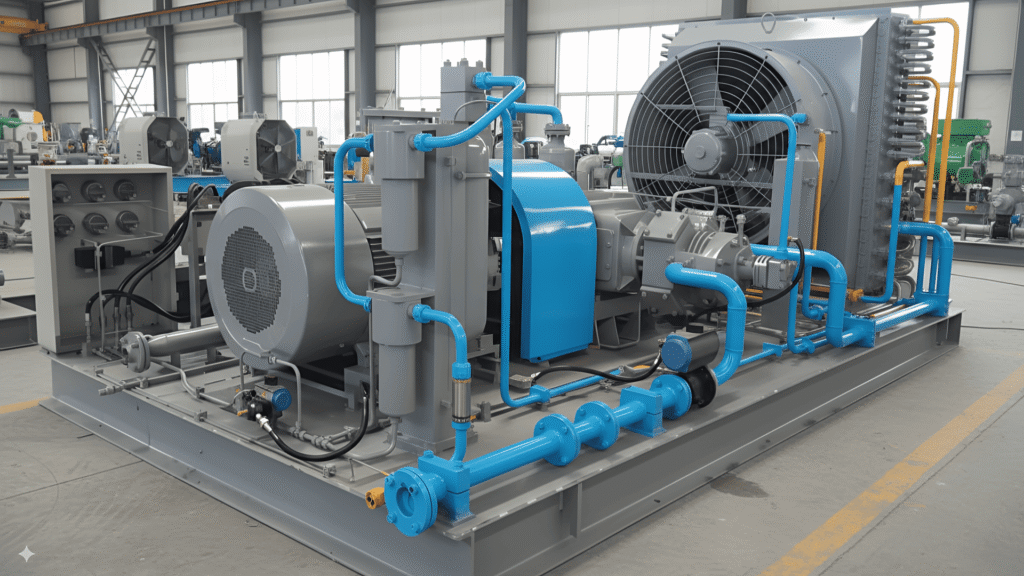

Rotary screw, reciprocating, and centrifugal compressors generate significant heat and air–oil interfacial area, promoting oxidation and deposit formation.

Antioxidants (amine/phenolic), AW agents where required, anti-foam, rust/corrosion inhibitors, metal deactivators; demulsifiers for water separation.

RPVOT (ASTM D2272), TOST (ASTM D943) for mineral systems, foam (ASTM D892), air release (ASTM D3427), rust (ASTM D665), deposit tendency (varnish/patch colorimetry).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3811

|

Oxidation Inhibitor

|

1.0 – 4.0

|

|

PX 3806

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3807

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3843

|

Demulsifier & Defoamant

|

0.05 – 0.30

|

|

PX 4005

|

Dispersant

|

1.0 – 3.0

|

Machine tool slideways require low stick–slip and predictable friction to preserve positioning accuracy under mixed lubrication with coolant contamination.

Friction modifiers (boundary-layer control), AW/EP, tackifiers for adhesion, corrosion inhibitors, demulsifiers and anti-foam tailored for coolant environments.

OEM slideway friction/stick–slip evaluations (e.g., Cincinnati Machine), demulsibility (ASTM D1401), rust (ASTM D665), foam (ASTM D892).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3845

|

Extreme Pressure/Antiwear

|

0.25 – 1.25

|

|

PX 3863

|

Corrosion Passivator

|

0.25 – 1.25

|

Large circulating systems (paper machines, turbines, bearings) demand long-life oxidation stability, rapid air release, and water shedding to sustain film thickness and cleanliness.

Antioxidants, rust inhibitors, demulsifiers, anti-foam; metal deactivators where copper alloys are present.

TOST (ASTM D943), RPVOT (ASTM D2272), air release (ASTM D3427), foam (ASTM D892), demulsibility (ASTM D1401), rust (ASTM D665).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3239

|

Copper Deactivator

|

0.02 – 0.05

|

|

PX 3827

|

Silver Deactivator

|

0.02 – 0.05

|

|

PX 3806

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3807

|

Premium antioxidant

|

0.05 – 1.0

|

|

PX 3863

|

Corrosion Passivator

|

0.25 – 1.0

|

Greases must retain structure while providing EP/antiwear protection and corrosion resistance under contamination, vibration, and wide temperature ranges.

EP (sulfur–phosphorus, solid lubricants where appropriate), AW, antioxidants, rust/corrosion inhibitors, tackifiers, anti-foam; metal deactivators for copper-bearing components.

4-ball wear/EP (ASTM D2266/D2596), copper corrosion (ASTM D4048), water washout (ASTM D1264), dropping point (ASTM D2265), EMCOR rust (ISO 11007).

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3239

|

Copper Deactivator

|

0.02 – 0.05

|

|

PX 3827

|

Silver Deactivator

|

0.02 – 0.05

|

|

PX 3849

|

Extreme Pressure/Antiwear

|

0.2 – 1.0

|

|

PX 3846

|

Extreme Pressure/Antiwear

|

0.2 – 1.0

|

|

PX 3861

|

Rust inhibitor

|

0.5 – 1.5

|

|

PX 3864

|

Rust inhibitor

|

0.25 – 1 1.5

|

|

PX 3865

|

Rust inhibitor

|

0.5 – 1.5

|

|

PX 3871

|

Friction modifier Grease Thickener

|

0.5 – 1.5

|

|

PX 3872

|

Friction modifier Grease Thickener

|

0.5 – 1.5

|

|

PX 3822

|

Dispersant Detergent

|

1.0 – 5.0

|

|

PX 4005

|

Dispersant

|

1.0 – 5.0

|

Severe boundary conditions at the tool–workpiece interface generate heat and adhesive wear; lubricity and EP chemistry are needed to prevent welding and extend tool life.

Friction modifiers/ester lubricity agents, sulfurized/phosphorus EP chemistries (chlorinated chemistries are often restricted), corrosion inhibitors, defoamers, biocide packages for waterborne systems.

Falex pin & vee block (ASTM D3233), 4-ball EP (ASTM D2783), tapping torque, foam (ASTM D892), copper strip corrosion (ASTM D130), staining tests per OEM/customer methods.

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3239

|

Copper Deactivator

|

0.02 – 0.05

|

|

PX 3827

|

Silver Deactivator

|

0.02 – 0.05

|

|

PX 3812

|

Friction Modifier

|

1.0 – 3.0

|

|

PX 3823

|

Dispersant/Detergent

|

dosage not specified

|

|

PX 3830

|

Emulsifier

|

dosage not specified

|

|

PX 3861

|

Rust inhibitor

|

0.05 – 1.0

|

|

PX 3864

|

Rust inhibitor

|

0.05 – 1.0

|

|

PX 3822

|

Dispersant Detergent

|

1.0 – 5.0

|

Drawing, stamping, rolling, and forging impose extreme pressures and sliding. Boundary-lubrication additives are essential to prevent scoring and achieve target draw ratios.

Sulfurized/phosphorus EP agents, polymeric/ester lubricity improvers, solid lubricants where applicable, corrosion inhibitors, emulsifiers for water-dilutable systems.

Cup drawing/limiting draw ratio, 4-ball EP/wear (ASTM D2783/D4172), Falex (ASTM D3233), staining/corrosion per substrate, residue/cleanability evaluations.

|

Product

|

Function

|

Dosage

|

|---|---|---|

|

PX 3239

|

Copper Deactivator

|

0.02 – 0.05

|

|

PX 3827

|

Silver Deactivator

|

0.02 – 0.05

|

|

PX 3823

|

Dispersant/Detergent

|

dosage not specified

|

|

PX 3830

|

Emulsifier

|

dosage not specified

|

|

PX 3861

|

Rust inhibitor

|

0.05 – 1.0

|

|

PX 3864

|

Rust inhibitor

|

0.05 – 1.0

|

|

PX 3822

|

Dispersant Detergent

|

1.0 – 5.0

|

Our consultants are ready to help you maximize performance with the right catalyst and performance additives solution.